HAZOP Workshop Facilitators

HAZOP Workshop Facilitation Case Study

We first worked as a HAZOP Workshop Facilitator in December 2011. We facilitated a HAZOP review of a processing plant for an engineering firm and their mining client. Since then we have partnered with other engineering firms to facilitate HAZOP workshops with their clients. We have worked on processing plants for Gold, Titanium, Anorthosite, Diamonds , Biodiesel and Olefin. Our clients are in the United States and Canada, with projects in the US, Canada, and South America. In September of 2020 we did our first virtual HAZOP meetings.

In this case study, we give an overview of the HAZOP Workshop Methodology and discuss some facilitation challenges. We also describe our use of HAZOP software to support the process.

What is a HAZOP study?

HAZOP stands for Hazard and Operability study. It is a group process for identifying potential hazards and operability problems. What we are looking for are deviations from the design intent of the plant. The design intent is what the plant is supposed to do. For example; “Safely and efficiently process x tons of ore per year into y ounces of gold.” A deviation is anything that is inconsistent with this intent. Hurting people, releasing pollution, damaging equipment, losing production, are all deviations.

Keyword Pairs

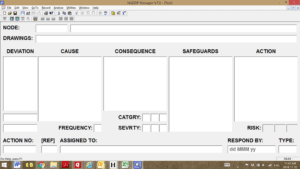

The HAZOP methodology uses keyword pairs as a brainstorming trigger. For a plant processing liquids we may use keywords like “no flow”, “reverse flow” & “over flow”. This list is created in advance of the meeting by the client and is documented by the facilitator. During the workshop the HAZOP facilitator walks the team through each step of the process using the P&ID. At each major step in the process, we review the list of keywords to see if it “triggers” a concern for any member of the team. We then discuss; causes, consequences, safeguards, and actions, for any concerns raised.

All of this is captured using the HAZOP software.

The Risk Matrix

We use a risk matrix to evaluate both the likelihood and severity of the deviation. We recommend using multiple categories of harm. Health and Safety is one. Another would be Environmental Impact. A third would be Financial Loss.

We also recommend the use of “anchored scales” to ensure that the group is in agreement. Instead of using “high”, “medium”, or “low” frequency, you should use, “daily”, “weekly”, “monthly”. For Health and Safety, your scale should go all the way from a “minor injury requiring first aid” to “loss of life.” You should also make sure that the amount of harm is equivalent across all categories at each step in the scale. If your fourth highest Health and Safety score is for “Permanent Disability” it would not make sense for the fourth highest Financial Loss to be “$5,000.”

Facilitation of the HAZOP Workshop

In opening the meeting it is important to clearly define the scope of the review. The scope helps ensure that we will not miss anything through oversight. Since we are looking for deviations from the design intent, it is imperative that you have a clearly stated design intent. A good example would be;

“The plant will safely and efficiently process 3 million pounds of ore into 100,000 ounces of titanium annually.”

Keeping the group focused

One of the challenges of a study like this is keeping everyone “on the same page.” In preparation for the meeting, you should break the plant into major sections or nodes. A good referencing notation for each node is critical. We use this to link the deviations logged in the software back to drawings. The facilitator then needs to keep the group focused on the node under review.

Whether using diagrams or the 3D models it is important to walk through each node under review twice. The first walk-through is to make sure that we understand what is happening. During the first pass, we limit our discussion to questions of clarification. The second pass is where the critical discussions take place. It is where we identify and evaluate the deviations from the design intent. The two passes help make sure that we don’t lose sight of the forest because of the trees.

Another facilitation challenge is the sheer volume of detail that we need to consider. The facilitator must be aware of the group’s energy, and focus, and take action when either is faltering. With one client we only worked five hours per day on the HAZOP. This really helped keep the group fresh and focused. It also gave them time each day to keep up with the never ending demands of email and phone calls.

Note Taking and Reporting

The facilitator also needs to be concerned about the quality of the documentation. A HAZOP is a long and detailed process and it is very easy to “move on” before the documentation is crisp, clear and concise. To address this we found it useful to review the documentation of the hazards a second time the next day. We improved the quality of the documentation every time we did this.

We also find it useful to maintain a separate “parking lot” of issues. This is used to record questions that can be easily answered and do not need full reporting. (e.g. Check to ensure valve seals are silicone and rated for ..). The parking lot makes sure that a lot of details that could be forgotten will not be overlooked.

We particularly like the automatic report generation capability of the software that we use. These automatic reports are a lot easier to use than an Excel spreadsheet. They can be run on demand, and saved as Word documents or PDFs.

Action Items and Follow Up

Action Items are the most important output from the HAZOP process. These Action Items are how you address the deviations that we uncover. Each one of them is an improvement over the original design. During one HAZOP that took seven days to complete we documented 126 improvements.

Each action item will have a defined owner, a deliverable, and a due date. As the action items are closed we update the software. It is important to note that open action items are not taken into account in risk scoring. We typically save one version of the HAZOP with the original risk scores. We save a second version with updated risk scores and safeguards after the action items are complete. There is always a significant improvement in the overall risk profile of the plant.

Virtual HAZOP Facilitation

Our recent client was extremely pleased with how their Virtual HAZOP meetings went. Using Zoom meetings we were able to break the HAZOP study into six four-hour long segments. This allowed us to be incredibly focused and productive. It also meant that no one had to travel, and everyone had time to address their day to day work. We used screen share throughout the meeting so everyone saw the notes in real time. At the end of each day we published interim reports.

HAZID

We have also been asked about HAZID and how it is different from HAZOP. Both are risk management tools. The primary difference is that a HAZID is driven from a checklist, whereas a HAZOP is driven by keyword pairs. We would be very happy to facilitate a HAZID and the software we use supports this.

HAZOP Software

Using Lihou HAZOP Manager 7.0 for documenting a HAZOPS review

We are licensed users of HAZOP Manager 7.0 from Lihou. The software saves time and leads to a better review and a better report. Here is a link to the Lihou site about the HAZOP software www.lihoutech.com

Do you need a HAZOP Workshop Facilitator?

If you are considering using a HAZOP Workshop Facilitator, please give us a call at 416 461 0715. You can also or send us an email at bwithrow@facilitators.com, or use our contact form. Contact Meeting Facilitators International